Arduino Hx711 Weight Scale Interface 1 0 Software

NOYITO 1kg 5kg 10kg 20kg Load Cell and HX711 Combo Pack Kit - Load Cell Amplifier ADC Weight Sensor for Arduino Scale (20kg+HX711) by NOYITO 3.0 out of 5 stars 1. I found a dead scale at work, the electronics were fried. I figured the load cell inside was still good, and would be fun to hack. I stripped out the load cell, and connected it to an Arduino with a HX711 amplifier /.

At the in London we hold repair events where members of the public are invited to bring in all manner of electrical and electronic items for repair, so as to save them from landfill. A few months ago (at an event I didn't actually attend) someone brought in some faulty kitchen weighing scales which nobody could fix. Never having seen inside any digital weighing scales and not knowing how they work, I took it as a challenge to research them, in the process, building two versions of my own. If you wish to build your own weighing scales or incorporate a weighing function in a wider project, you can use this Instructable as a basis, whatever your requirements, from weighing fractions of a gram up to many kilograms. Hence I will concentrate on the electronics, the software and the underlying principles. How you realise your own project is completely up to you. I will also show you how to calibrate them, even if you don't have any standard weights.

Having done my research and having validated it by building my own scales, I wrote up the principles of weighing scales, including whatever I could deduce about fault-finding, in the Restart Project. Go and take a look!

All digital weighing scales are built around either a 4-terminal load cell or four 3-terminal load cells. Which to get depends on what sort of scales you want to make. They are all electrically compatible and fairly cheap so you can change your mind later, or get more than one type to experiment with.

For kitchen or postal scales with a maximum load in the range of 100g to 10kg, you can get 4-terminal load cells consisting of an aluminium bar. This is mounted horizontally, supported at one end and supporting the weighing platform at the other. It has 4 strain gauges attached to it. Autocom cdp usb driver.

I explain fully how it works in my article so I shan't repeat it here. These are less suitable for heavier loads such as bathroom scales, where a person's full weight, not necessarily centred on the platform, is better supported by 4 load cells supporting the 4 corners of the platform. This is where four 3 terminal load cells are more suitable. Ones rated at 50kg each are widely available, which together will weigh up to 200kg. Others with even higher ratings are designed for suspending the weight to be measured after the fashion of luggage scales. In addition to your load cell or load cells, you will need: • An Arduino. You can use virtually any type you like but I used the Nano as it has the USB interface built-in and still only costs a few pounds.

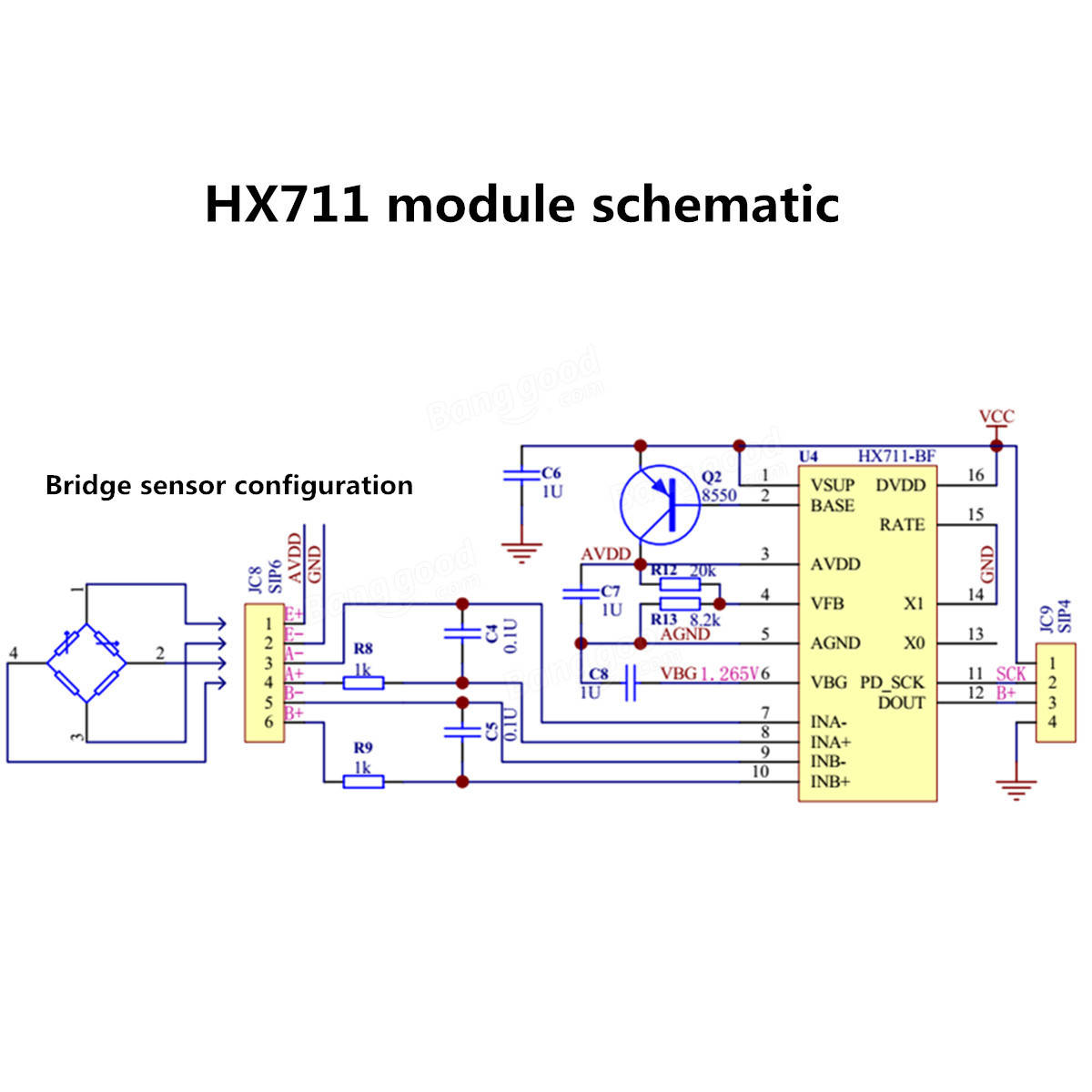

• A HX711 module. This may come bundled with your load cell but is available very cheaply as a separate item from many sources. • For prototyping, a 400 point breadboard, jumper leads, pin and socket strips. You will also need wood, plastic, screws, glue, or whatever you require for your particular version of the project.

To use the HX711 module on the breadboard, solder a 4-wide pinstrip to the interface pins (GND, DT, SCK, VCC) of the HX711. For easy connection and disconnection of the load cell (particularly if you're experimenting with more than one sort) solder a 6-wide pin socket strip to the analogue pins. (You only need the E+, E-, A- and A+ pins but I fitted a 6-wide strip anyway in case I wanted to experiment with the other two.) If you are using a 4-wire load cell you will then need to solder the 4 leads from the load cell to a 4-wide pin strip. The first two pins will be E+ and E- and the other two A- and A+. I taped over the solder joints with PVC tape to protect them.

A mark on one end and a corresponding mark on the pin socket means I know which way round to connect it, though I don't think it matters. Different load cells colour code the wires differently, but it's easy to tell which is which. With a test meter on a resistance range, measure the resistance between each pair of wires. There are 6 possible pairs of 4 wires but you will only get 2 different readings. There will be 2 pairs which read 33% more than the other 4, say, 1,000Ω instead of 750Ω. One of those pairs is E+ and E- and the other is A+ and A- (but it doesn't matter which).